The magic of Oigawa Mempa

Hana picked me up at the Shizuoka Station and we headed north. After about an hour’s drive, we reached Oiya 大井屋, the shop and the studio where Hana chose to work after graduating from the Traditional Arts Super College of Kyoto (TASK).

The shop looked far from fashionable boutiques in Tokyo or Kyoto. Why a young woman like Hana had chosen this place as her workplace, I wondered.

Mr. Maeda, Hana’s boss, greeted me with a big smile. “Let’s have lunch together.” Hana had already prepared lunch for three of us, neatly packed in, nothing else, their own Oigawa Mempa.

Hana’s bento in their Oigawa Mempa – photo by Author

What is Mempa

A thinly-sliced wood is bent to form the side of the container… While similar types of this woodworking technique are found throughout Japan, it varies depending on the regions as to which wood is used, how the coating is done, and what people call them. In the Oigawa region, the mountainside of Shizuoka Prefecture, people call such wood containers “Mempa.”

Hinoki cypress trees that grow locally are used for the body. Strips made of the local cherry tree bark are used to stitch together the edges. Kakishibu is used for the undercoat, and Urushi sap for the overcoat.

Oiya is the only place remaining to make this type of wooden lunch boxes exactly the same way as has historically been made, using only natural materials.

Shaping, Bending, Stitching, and Gluing

After lunch, Hana and Mr. Maeda led me to the workspace to walk me through the process of making their Mempa.

Hinoki Cypress wood board is first boiled in hot water so that it becomes soft enough to bend. By rolling it with a cylinder-shaped tool several times, the boiled board is gradually bent.

Hana is making the side board bent – photo by Hana with permission

By holding the edges of the board together with a special tool, they cut out slits and stitch together the edges with the cherry bark strip.

Stitching the edges of the bent wood with the strip of cherry bark – photo by Author

The side body is made by bending thinly sliced hinoki cypress. The edges are stitched together with a strip of cherry bark – photo by Author

Once the side of the container is formed, they put it together with the bottom part.

The bottom of the lunch box is also made of hinoki cypress– photo by Author

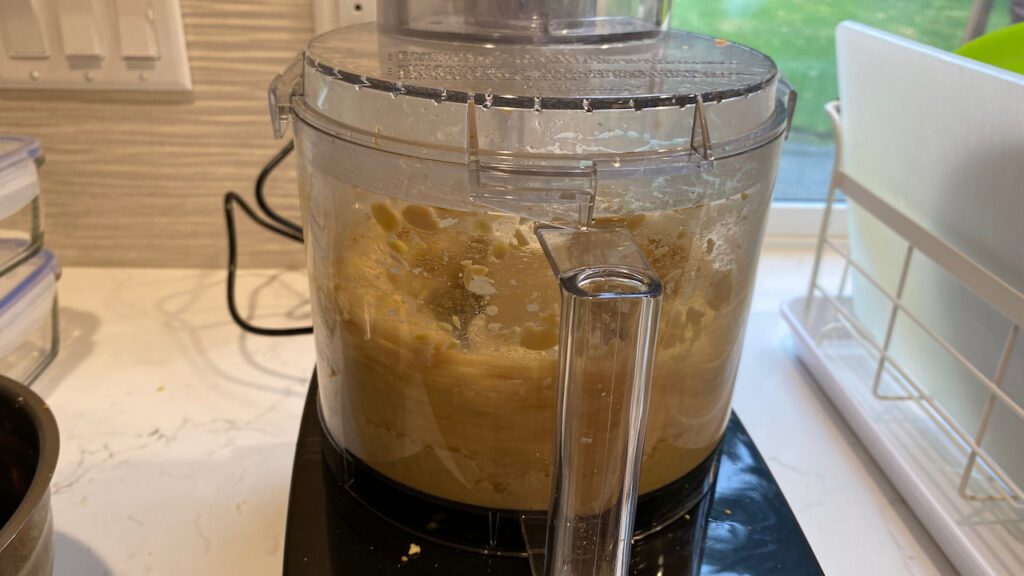

Mugi Urushi 麦漆, paste made by mixing Urushi sap and flour, is used to glue together the bottom and the side of the container. The gluten of flour mixed with Urushi creates a strong bond once the paste dries.

Next Sabi Urushi 錆漆is applied on top of the stitches and the gap between the bottom and the side of the container. Sabi Urushi is a mixture of Urushi sap and diatomite. With finer particles, Sabi Urushi gives a smoother texture than Mugi Urushi, as well as filling the tiny gaps.

Hana applies Mugi Urushi麦漆 to glue together the bottom and the side of the container – photo by Author

Hana applies Sabi Urushi錆漆 onto the threaded bark to smooth out – Photo by Author

Both Mugi Urushi and Sabi Urushi are applied, now drying – photo by Author

Mugi Urushi hardens after a day or so, but it takes at least 3 in the summer and almost 2 weeks in the winter for Sabi Urushi to completely harden.

Undercoating, Overcoating, and Decorating the Surface

The next step is to undercoat the body with Kakishibu.

Kakishibu 柿渋 is the fermented juice of unripe persimmons. For centuries in Japan, Kakishibu has been used to protect wood, fabrics, and paper from moisture, insects, and fungi. Its antiseptic and antibacterial properties have now been scientifically proven.

For Oigawa Mempa, they apply kakishibu undercoating 4 or 5 times. Why apply kakishibu so many times?

Hinoki cypress is a comparatively soft wood, therefore, it is easy to bend. “Soft” also means it is easily scratched. By applying kakishibu 4 or 5 times, the wood becomes harder and more resilient to scratches, as well as lighter, because the moisture in the wood is eliminated.

“We apply Kakishibu on a sunny day, in a workspace outside in the shade. After each time we apply Kakishibu, we place it under the sun. When the layer is dried, we apply another layer. We repeat this process 5 or 6 times. Interestingly, I can feel the wood gets noticeably tighter and lighter after the third or fourth layer,” says Hana.

Oigawa Mempa after Kakishibu is applied and dried – photo by Hana with permission

Once the Kakishibu undercoat is applied, now it’s time to apply Urushi overcoat.

The beautiful, shiny surface is the signature characteristic of Urushi. Also, it adds water resilience, strength, and durability to the surface. It also has antibacterial properties. No wonder Urushi has been used for bowls, plates, and almost every form of food and drink containers in Japan for centuries.

Hana is applying Urushi overcoat – photo by Hana with permission

Urushi is an interesting material. Although people call the process “drying Urushi,” it’s actually a chemical reaction of hardening the substance, which requires high humidity. Once the overcoat is applied, the containers are kept in the “muro, ” the cabinet full of shelves. Mr. Maeda opened the sliding door of the muro, where the containers were dried. Before closing the door, he sprayed water onto the shelves to make sure to keep the humidity in the muro at about 80%.

Mr. Maeda is spraying water onto the shelves – Photo by Author

The surface hardens in about a day in the muro. Urushi may still irritate the skin until it completely hardens. Oiya waits at least a week before moving the containers to the storefront.

Each Mempa displayed in the showcase has a tag that tells when it was taken out from the muro. Oiya suggests that customers wait for two months in the summer or three months in the winter before they start using the Mempa they purchased.

Completed Mempa on display – photo by Author

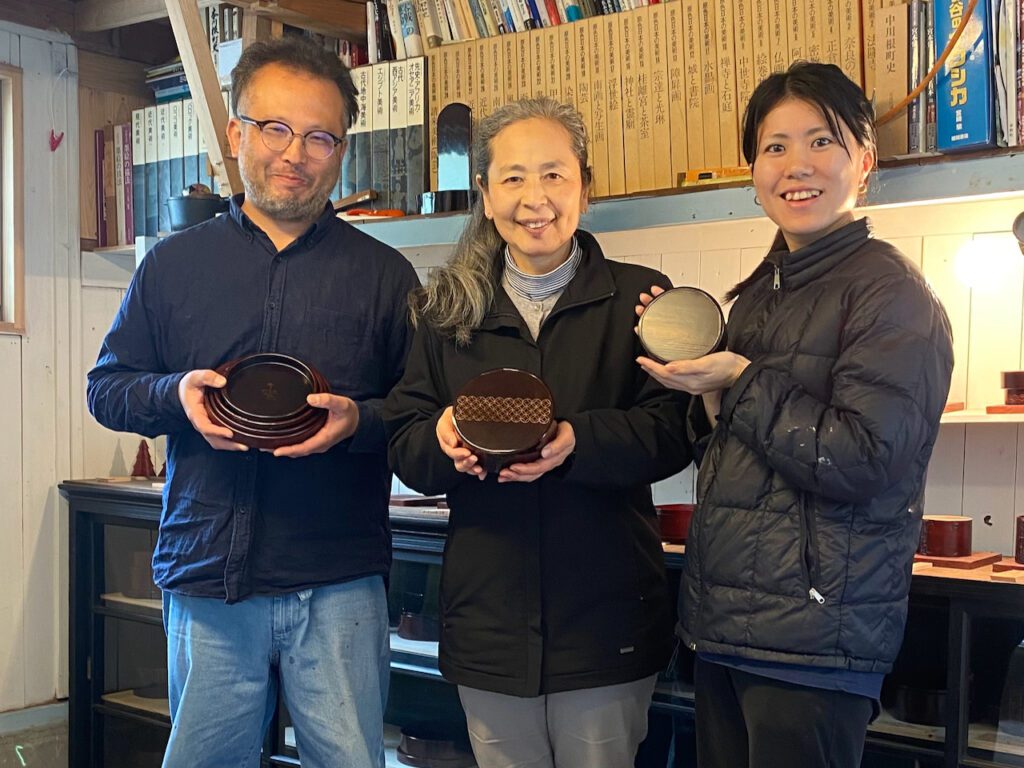

Oiya’s Mempa used to have just a plain surface. For Hana, who learned Makie 蒔絵 design at TASK, the plain surface has become a new canvas to try new designs. She first added Japan’s traditional designs. Now she takes orders for custom designs.

Hana is applying Makie designs on the lid – photo by Hana with permission

Mempa with Hana’s Makie designs – photos by Hana with permission

So how long does it take to make a Mempa? About how many Mempa does Oiya make in one batch?

From the start, when they cut the wooden boards, to finish, when they put them on the storefront, it takes about 3 months. For each batch, they make 80 to 90 Mempa. With two of them, they are making roughly one Mempa a day.

***

Every summer, they make their own Kakishibu from organic persimmons that are locally harvested. They purchase rough Urushi生漆 from a wholesaler, but they don’t depend on a third party to refine it. They don’t mix any thinning solution to Urushi. Rather, they make Urushi softer by painstakingly mixing it in the sunlight.

Mr. Maeda shows no compromise when it comes to the materials they use and the process they use to make their Mempa.

“Mempa is used to store our food, which is indispensable for our body and health. How can we compromise its quality?” says Mr. Maeda.

Beside him, Hana was nodding each time Mr. Maeda made his comments. I remembered that Hana had mentioned in her essay that her dream job would be to make lacquerware that are used by people every day. Kudos to Hana for making her dream come true.

Mr. Maeda, Hana, and me with Mempa in our hands – photo by Author

Hana will be coming to Seattle this summer. For the Mempa I ordered, I asked her to design something that depicts Seattle. What kind of design will she come up with? I look forward to finding out!