Craftsperson’s passion and skill are applied with Urushi

Katsuyama-san’s Obi uses ultra-thin gold threads. How are the gold threads made? Who makes them?

Katsuyama-san’s van left his studio in Shuzan 周山, the countryside of the northern part of Kyoto City. Those questions were answered at the next destination, a little closer to the city center.

A man whose name was Saito-san, with a large apron, greeted us with a big smile. Saito-san’s workplace was a low desk. He sat in front of the desk, and we sat on the other side as he started working.

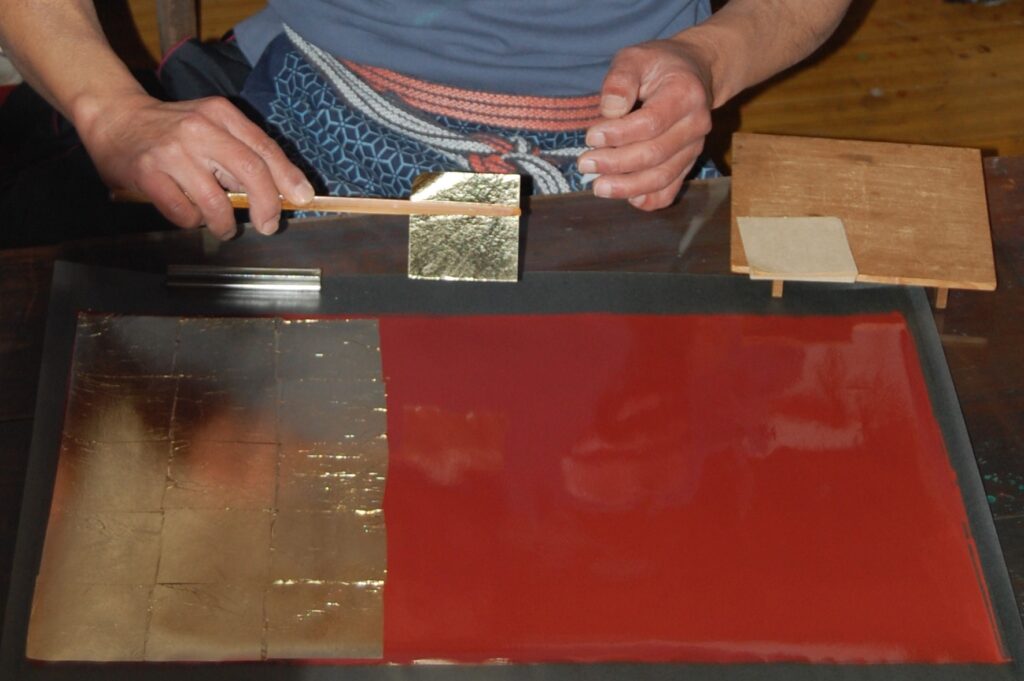

At first, Saito-san placed a sheet of red washi paper made from Oriental paper bush, on the desk. On the washi paper, he spread urushi evenly. He seemed to have already got immune to urushi, because he was not wearing gloves.

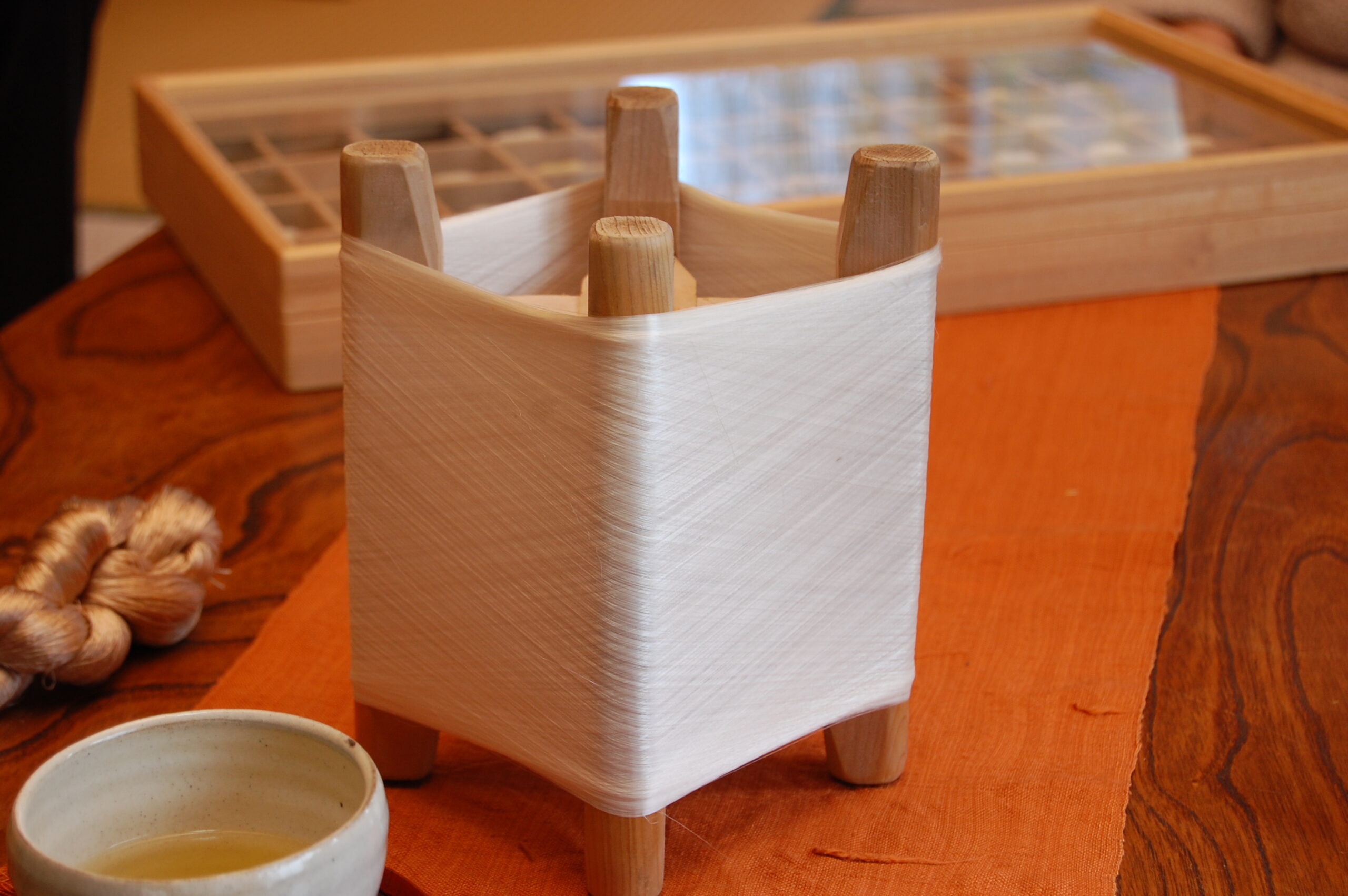

Then he opened a package covered with white paper. Inside there were sheets of square, ultrathin gold film. He picked up one sheet using a tong made of bamboo and held it up in the light. The film was so thin that you could almost see through it.

Saito-san swiftly placed the gold film at the edge of the red paper. He pressed it evenly, picked up another gold film, placed it right next to the first one, pressed it evenly, picked up another one, placed it right next to the second one, pressed it evenly, picked up another one…

While answering our random questions, he continued his work. Five sheets in one row, and five rows on one sheet of paper. In total, he placed twenty-five sheets of ultra-thin gold film onto washi paper so effortlessly. There was no gap in-between the films, nor any overlap.

After he finished placing the gold film, he rubbed the surface with a special tool, creating a rustic look.

“The task is quite simple. What makes our work different from those of amateurs is the speed and consistency. After repeating it so many times, I can do it quickly, yet there is very little difference in how each sheet looks. That’s the work of a craftsman like me,” said Saito-san.

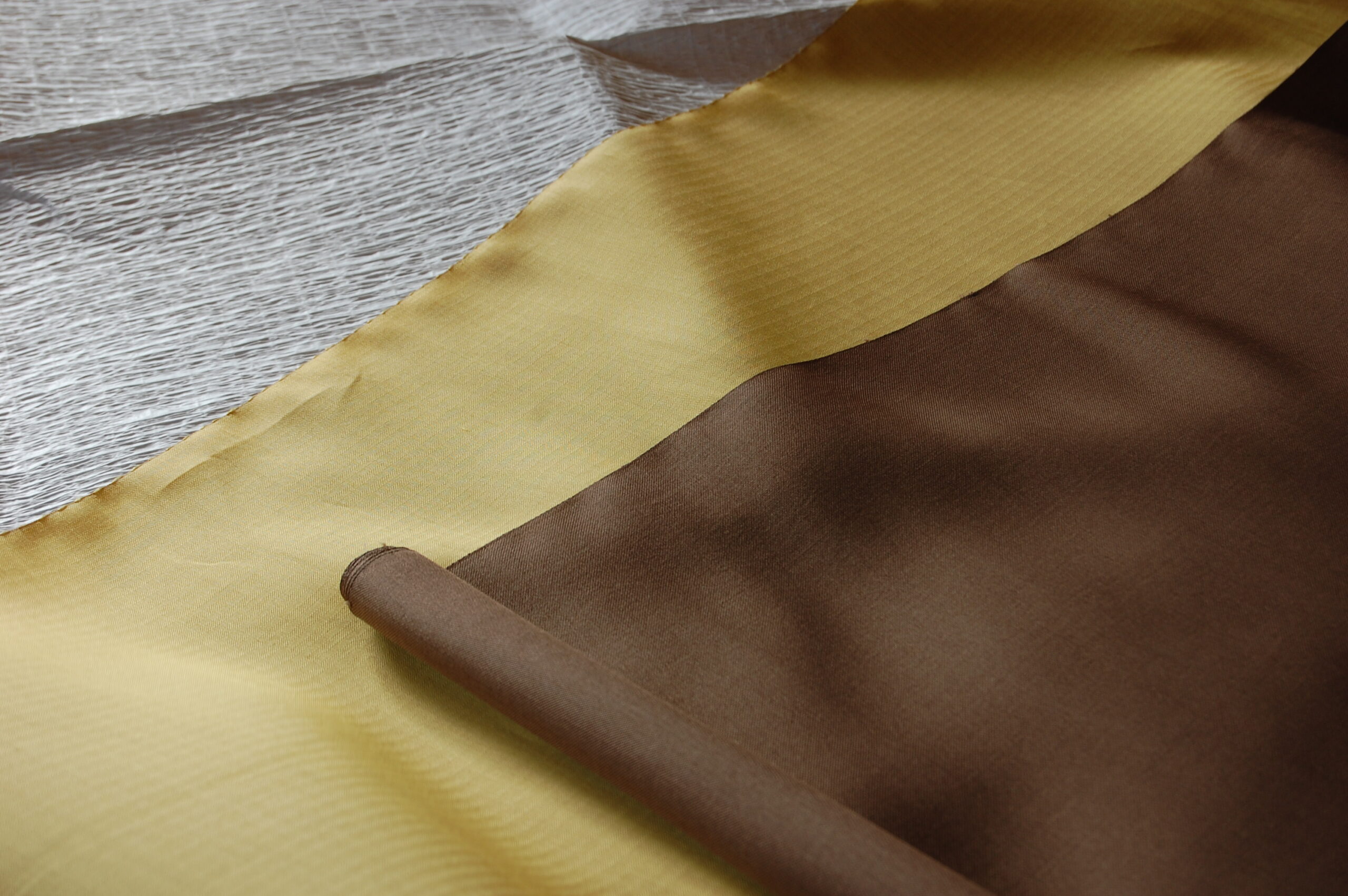

He showed us the sheet cut into thin thread, with sample of red fabric that was woven together with the gold thread. (See the first photo above.)

“How many people are working for you?” I asked.

Saito-san said, “Are you kidding me? No young people want to do such tedious work. When I retire, there is nobody that would take over my job here. I’m more than sixty years old. I will try to continue as long as I can.”

I hope Saito-san is not the only hikihaku (引箔) craftsman in Kyoto, but he is the only one whose work Katsuyama-san can fully trust.